Derwent Valley cotton-mill towns

Cromford

Derwent Valley mills: among the most important preserved industrial sites is Arkwright’s factory of Cromford Mills (26 km N of Derby).

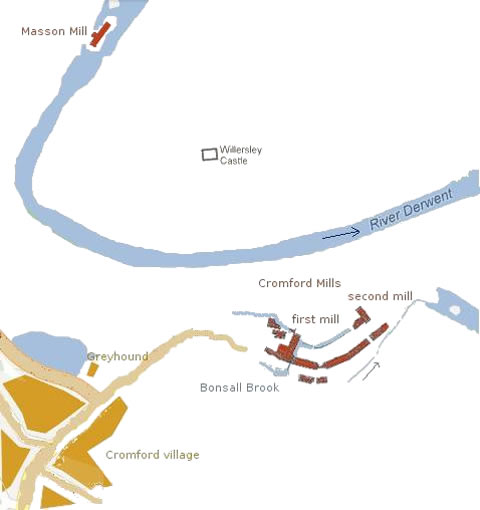

- Map of Cromford

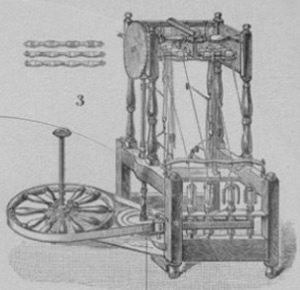

- Cotton spinning

- the cotton spinning machine invented by Arkwright (early 19th century engraving after the drawing in his 1769 patent)

[click on the picture to enlarge it]

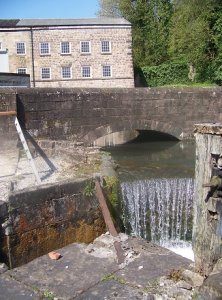

- Cromford Mills

- [click on the picture to enlarge it]

A general view of the Cromford Mills site from the entrance (East); the ’First Mill’ (1771) is the sunlit building in the distance to the centre of the picture (slightly to the right); the ’Second Mill’ (1776) is the foregound building to the right (partially seen), only an extension remaining. The range of buildings in the shade from the centre to the left (South) were offices and warehouses (1783 onwards).

- First Mill

- [click on the picture to enlarge it]

- Second Mill

- [click on the picture to enlarge it]

Two views from within the site, one (far left) towards the First Mill showing one of the weirs, and the other (left) in the opposite direction towards the Second Mill, showing the uses of streams.

The First mill was built with a width corresponding to the largest beams which could cover the space for the machinery. The water power used came from Bonsall brook (partly under culverts), and a stream formerly used by lead mines; the level was raised to have ’overshot wheels’ (= wheels driven by water falling over them, which makes for a stronger current, not running under them).

The factory had 8000 operatives, of different trades; Arkwright advertised in the Derby Mercury for ’clockmakers that understand tooth and pinion’ - here as in other fields, clocks were models of machinery.

The mills worked round the clock.

The site was depicted in two paintings by Wright of Derby (1782), one by night, a view from the hill, with the First Mill in front, and the Second Mill beyond. It also appeared in a painting by Zachariah Boreman (1787), used in 1795 to decorate saucers of Derby china.

- The Derwent from the Mill

- [click on the picture to enlarge it]

- Masson Mill

- [click on the picture to enlarge it]

- Masson Mill

- [click on the picture to enlarge it]

Two views of Masson Mill (1783), one (centre) taken from upstream (N) towards the Mill showing its relation to the Derwent, the other one showing the entrance - which is inland facing, to the right of the first photo. The view of the entrance shows how classical practices were adapted to industrial architecture: the projecting centrepiece - a usual practice, emphasised by the Venetian windows - is actually used for technical purposes, to house the wheel and the vertical shafts driving the machinery across the floors.

The Derwent from the Mill, upstream, showing the weirs and the steep slope from the hills providing sufficient force to drive the machinery - the steepness of the valley may be estimated from the format of the photo, a vertical panoramic view stitching three shots.

The village built for the workforce, viewed from the entrance of the village: to the right of the street, the Greyhound, an inn for visiting merchants.

Willersley Castle, overlooking the valley, built by Arkwright for himself from 1786 when he was knighted.

- Cromford village

- [click on the picture to enlarge it]

- Willersley Castle

- [click on the picture to enlarge it]

Belper

Belper is 14 km N of Derby. The mill owners were Jedediah Strutt (1726-97) and his son William Strutt (1756-1830), who bought St Helen’s house in Derby; as a member of the Derby Philosophical Society with Erasmus Darwin, Boulton, Wedgwood, and Owen, he developed skills as an engineer. The third generation - an MP - was raised to the peerage in the mid 19th century.

A problem with nascent industries was that the amount of coinage in circulation was insufficient for the new needs - paying the workforce and buying goods. The Strutts solved it through their family links with bankers.

- The North Mill, Belper

- View from the opposite direction showing the water management system; the North Mill is the building in the middle, the larger building to the left dates from the early 20th century.

[click on the picture to enlarge it]

- The North Mill, Belper

- The arched entrance in the distance with gun embrasures to defend the precincts, and the mill - the brick building in the middle to the right of entrance; the river flows to the left beyond the buildings.

[click on the picture to enlarge it]

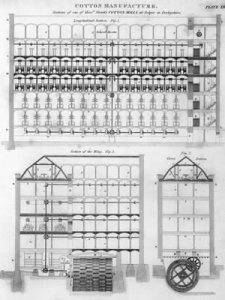

- The North Mill

- [click on the picture to enlarge it]

The North Mill was built by Jedediah Strutt in 1776, rebuilt by William Strutt in 1803 after a fire, as a fireproof structure of brick and cast iron. It rests on cruciform column arches linked by wrought iron beams ; the area above the wheel is covered with hollow clay pots (which are light) with iron beams and ties. The horizontal and vertical shafts run through the whole length and height of the mill.

The top two floors were used for carding, the lower two for spinning, the attic was a school room. There was a heating system.

The image (where minor inaccuracies have been traced by modern scholars) is from Rees’s Cyclopaedia (1811), showing that the mills were already seen as a technological model.

Belper village 1789-92:

- Belper village

- [click on the picture to enlarge it]

- The hospital

- [click on the picture to enlarge it]

A street of workmen’s houses: in such houses, it was not necessary to follow the classical practices of horizontal rooflines, leading to staggered cornices on sloping streets as in Bath and Bristol; here instead the houses have continuous sloping roof lines.

The hospital, with a heating system.